Need a 5 Axis CNC Machine?

- Patrick

- 2021年9月8日

- 讀畢需時 5 分鐘

5 axis CNC milling is well known. When I’m networking or meeting with clients, the question I get the most is “Do you have five axis machines?”. Unfortunately, I have to say no, but there are good reasons for it. The main reason is that we generally do high quantity orders with lower part complexity, the second being the cost of 5 axis machining centers.

While we don’t have 5 axis machines, 3+2 and 4 axis machines fill the roll. 5 axis and 3+2 axis machines hardware wise are similar, but the process of machining is different. On a 3+2 the two additional axes move independent of the 3 main axes. The additional 2 axes on a 3+2 machine are for rotation and indexing, ideal for plane processing (machining on different sides of the part). This means the machine will stop machining, rotate the part then continue machining. This post will cover the basics of which machine to use for manufacturing parts.

When to use a 3 axis machine:

3 Axis machines have a bed that moves on the X and Y axis. So toward us and away and left to right. Z is the spindle, up and down. 3 Axis machines are best for high quantity single face operations, tapping and drilling.

Example:

The upper and lower parts of a minimalist wallet could be milled on a 3 axis machine. Here we could make a pallet maybe 5 x 5. Half front and back. The 3 axis machine would produce the parts then the operator swaps out the pallet with another prepared pallet.

Why not always use a 3 axis machine?

The greatest cost comes in the form of labor. If your engineer/machinist has to stop what he is working on to simply flip a part and re-index it adds cost. These interactions are called setups. The less setups the lower the costs and less error due to setup variance. In parts manufacturing every cost counts. Ideally you would design the parts to manufacture (DFM or design for manufacturing) in the simplest way possible. Sometimes the part will require machining on different faces. Often each face may require a different fixture. It is possible to use an angle head with a 3 Axis machine, but in our case we can use our 4 axis machines.

Example:

We recently used a 3 axis machine to produce a part that required 3 different vise to be set up one for each face of the part. The part would move from the first vice to the second to the third. The setup and movement time added almost 1.5mins per part. At 300 parts that would come out to 7.5 hrs. Almost an entire workday. It also introduced errors as a few parts slipped while being machined. Take setup time + failed parts + the engineering time to design and machine the fixtures and the job becomes barely profitable. This of course is an exaggeration as machines with more axes also require setup time. Normally, a job like this would be done on a 4 axis machine and require one setup but our 4 axis machines were backlogged.

When to use a 4 axis machine:

When you're focused on volume and efficiency but parts require multiple face operations. A 3 Axis machine equipped with a rotary table is a 4 axis machine.

Trunnion tables are a type of rotary table, they are commonly used as they give a large working footprint. Think of a trunnion as a rotatable table top, it allows us to rotate around the X axis, this is referred to as the A axis. Part batches can be located on both sides of the table. As the table rotates it can machine different part faces. It can also be indexed at angles for different tool approaches.

Example:

Imagine that our minimalist wallet is one piece instead of 2 halves fastened together. We have to make 10,000 of them. Here is where a 4 axis machine would shine. We could machine the top bottom and then the middle all in one cycle. This is done by rotating the trunnion and indexing to the correct angles.

When to use a 3+2 machine:

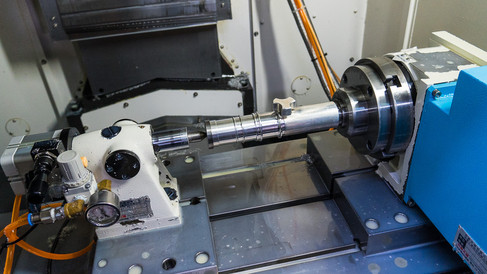

3+2 machines offer the same advantages as a 4 axis machine albeit with the ability to rotate on the Y called the B axis. The trade off is that we have to replace our trunnion bed with an additional rotary table reducing the amount of machinable parts down to one. Assemblies that consist of AB rotation take a lot of machine space. The B axis is great for round parts or parts with complex faces or non perpendicular face angles. It is possible to use a 3+2 machine much like a 5 axis machine but it requires an engineer with a high skill level.

When to use a 5 axis machine:

5 Axis milling is useful for creating highly complex parts generally at low volumes. Organic or rounded shapes benefit from 5 axis milling. Extreme angles can also be milled even parts with nested features. There are advanced applications and techniques only possible on 5 axis machines such as helical rotors. This means that 5 axis machines are often the best if not the only choice for certain parts.

Example: A hip replacement is a very organic shape and different for each person, this type of part would be produced on a 5 axis machine.

Why not always use a 5 axis?

It all comes down to cost and efficiency. 5 axis machines are the most complex machines you can purchase, meaning they are among the most expensive CNC machines. What this means is that the type of work that is done has to justify the initial investment. Native 5 axis machines come with better machine software which optimizes workflow and reduces complexity. 5 axis machines of the same dimensions offer larger working space as the rotary axis are built into the machine rather than on top of the work bed. While there are price savings in the reduction of secondary operations, usually a 3+2 machine offers enough flexibility on most parts.

Final thoughts:

Right, that sure was a lot of information, I can see why people give me a confused look when I talk about CNC machines. 3+2, 4.5 axis machines are not true 5 axis machines and should not be labeled as such, while they do each have 5 axes the way they work is fundamentally different.

To summarize, 5 axis machines are the most capable milling machines, great for contouring complex parts, but they aren’t always best for high volume production. 4 axis machines are our go to for parts requiring different face operations and 3+2 machines are used for the most demanding of parts.

留言